Product Introduction

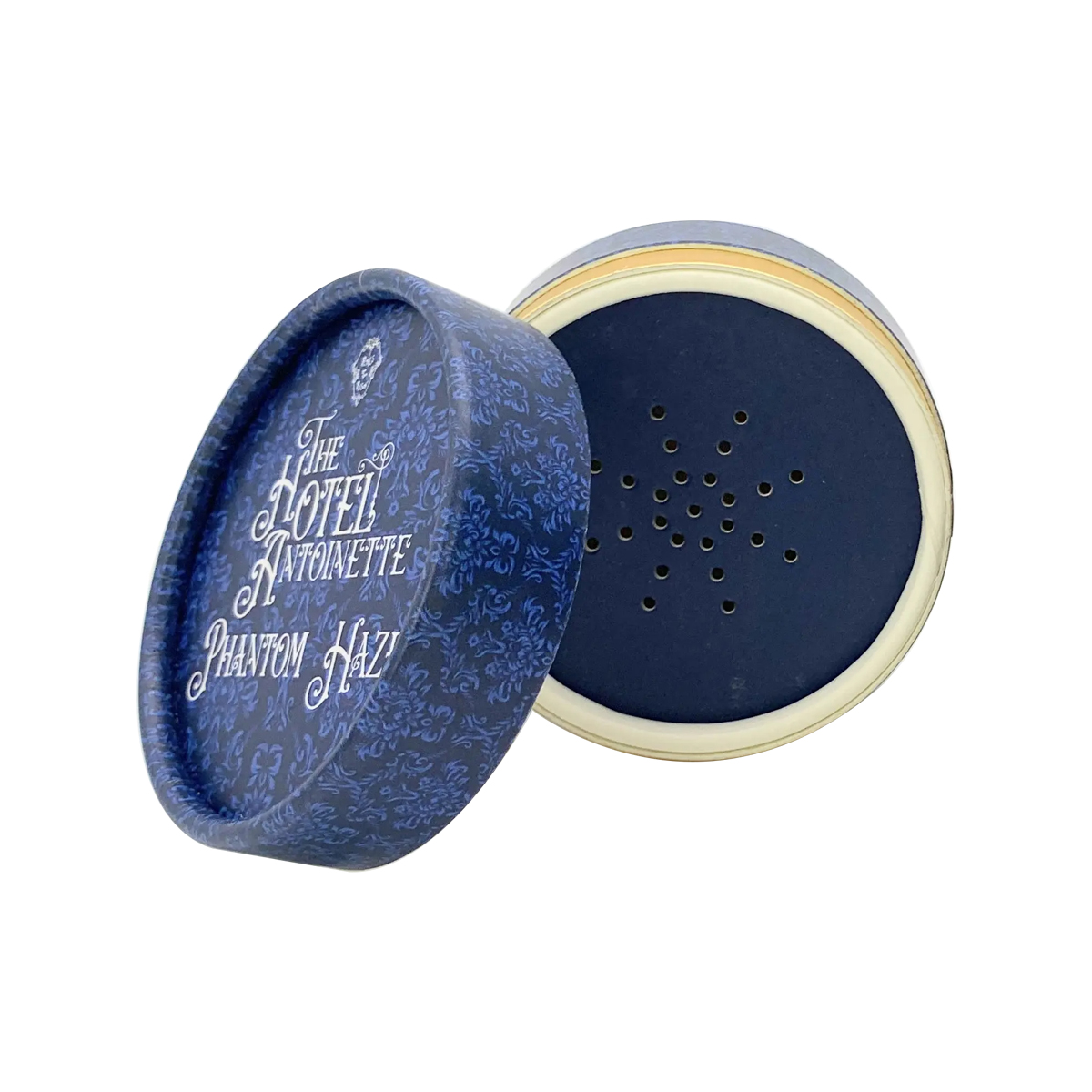

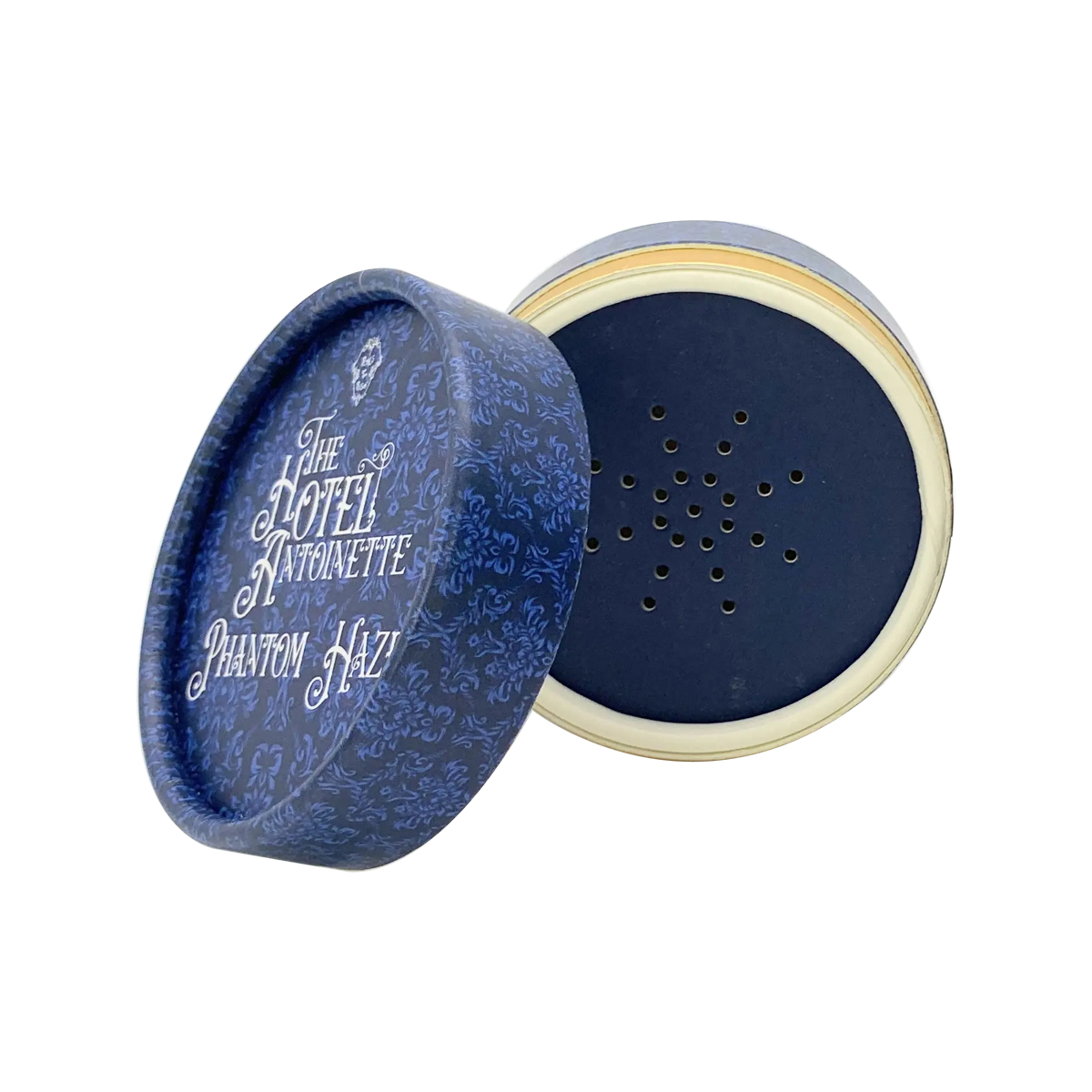

Custom Bath Salt Paper Tube Packaging Box with Paper Sifter

Paper Tube Specification:

Industrial Use: Suitable for gift, craft, food, electronic, cosmetic, and mailing industries.Custom Order: Custom orders are accepted, with OEM and ODM one-stop service available.

Outer Material: Surface Art Printing Paper combined with Cardboard.

Inner Tray Material: Paperboard, Art Paper, Corrugated Board, Coated Paper.

Paper Weight: 120g - 140g for the outer surface.

Color Options:

Printing options include:

CMYK (Cyan, Magenta, Yellow, Key/Black).

CMYK + 1 PMS Color (Pantone Matching System).

CMYK + 2 PMS Colors.

CMYK + 3 PMS Colors.

Finishing Options:

Various finishing options available to enhance the appearance and protection of the packaging, including:

Glossy or Matt Lamination.

Gold or Silver Foiling.

Embossed or Debossed patterns.

Spot UV coating.

Raised UV printing.

Varnishing or Polishing for added shine.

Glitter Powder for a unique, eye-catching look.

Additional Features:

High Light: This packaging is suitable for art printing recyclable tube packaging. It is eco-friendly and recyclable, featuring a paper weight of 120g, making it ideal for environmentally conscious consumers.

Use Case: It's perfect for packaging various items, such as gifts, crafts, food products, electronics, cosmetics, and mailing materials, while maintaining a premium and customizable appearance.

These specifications should help you create or source industrial use packaging that meets your requirements for different industries and customization needs.

Paper Tube Features:

1. Sturdy and Durable: This shipping box is designed to be sturdy and durable, effectively protecting the products inside from damage during transportation and handling.

2. Bespoke Design: The box features a bespoke design with a custom size and printed logo, allowing you to create packaging tailored to your brand's unique requirements.

3. CMYK Printing: The box's surface is printed using CMYK color printing, giving the cylindrical box a colorful and artistic appearance, making it stand out like an artwork product.

4. Gold Foil Stamping: The logo on the box is adorned with gold foil stamping, making your brand name and logo eye-catching and adding a touch of luxury to the packaging.

5. Luxurious Impression: The packaging is designed to create a luxurious impression, akin to receiving a gift, which can enhance the overall customer experience.

6. Environmentally Friendly: This cylindrical packaging box is environmentally friendly, making it an eco-conscious choice for your brand.

7. High-End Presentation: The high-end packaging box reflects the quality and exclusivity of the products it contains, emphasizing their premium nature.

8. Multi-Purpose: After receiving the products, the box can be repurposed as it can be painted and reused for storing various items, making it a functional and sustainable choice.

These features highlight the durability, customization, and aesthetic appeal of the shipping box while emphasizing its eco-friendliness and versatility for a variety of purposes.

Paper Tube Images:

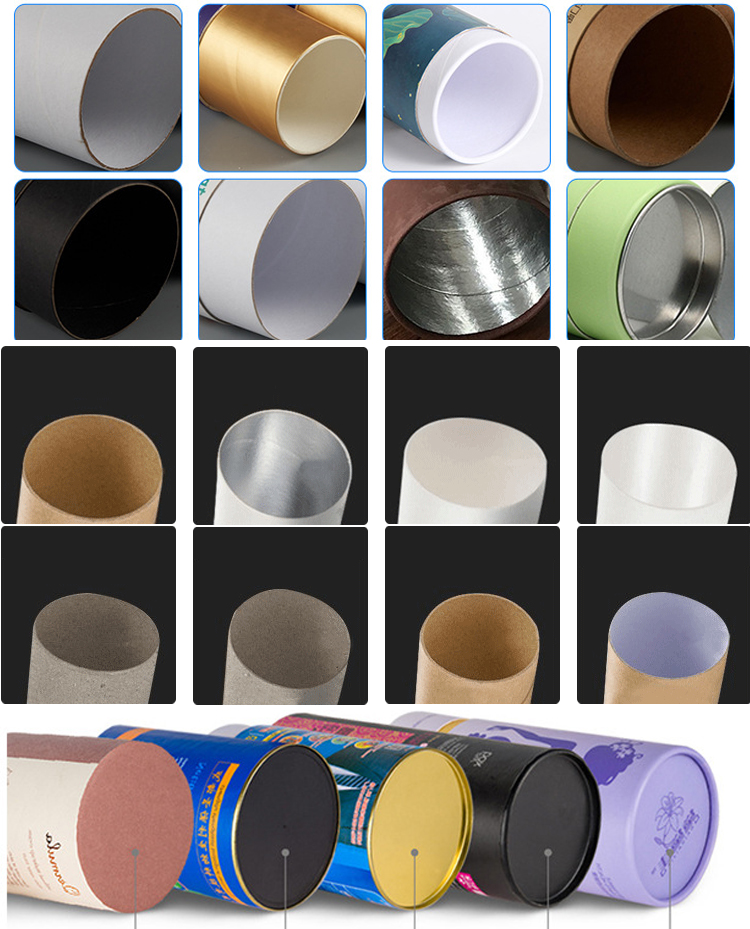

Materials of Paper Tube Packaging:

When it comes to ensuring sustainable paper tube packaging, the key lies in offering a diverse range of cardboard stocks that cater to various client specifications. At our disposal, we have an extensive selection that includes rigid paperboard, corrugated paper for added strength and durability, art paper for enhanced aesthetics, fancy paper for a unique touch, leatherette paper for a luxurious feel, pearl paper to add a touch of elegance, and even specialized options like gold and silver cardboard stock.

Moreover, our repertoire extends to include food-grade paper, ensuring that the paper tube boxes produced not only meet but exceed safety standards for packaging edibles or sensitive products. We continually strive to expand our collection, always seeking out innovative materials that align with sustainability goals without compromising on quality or functionality.

By offering this comprehensive array of cardboard stocks, we empower our clients to craft paper tube packaging solutions that not only meet their specific needs but also contribute to environmentally friendly practices. Sustainability isn’t just a feature; it’s a commitment embedded in our offerings, supporting the creation of packaging solutions that are both eco-conscious and versatile.

Surface Finishing of Paper Tube Packaging:

When it comes to elevating the visual appeal and overall impact of paper tube packaging, the options for enhancing its presentation are diverse and plentiful. Once the printing process is completed, a plethora of surface finishing techniques can be expertly applied, ensuring that your packaging not only serves its practical purpose but also stands out as a distinctive and memorable representation of your brand.

One of the classic choices to enrich the packaging is through the application of lamination. Here, the possibilities are vast: matte lamination offers a sophisticated, velvety texture that exudes an understated elegance, while glossy lamination provides a sleek, reflective surface that captures attention and radiates a polished look. The allure of soft-touch lamination lies in its tactile appeal, invoking a sensation of luxury and refinement upon touch.

For those seeking a touch of glamour and allure, the addition of glitter coating can transform your paper tube packaging into a dazzling spectacle, catching the light and captivating the eye. Furthermore, the timeless technique of hot foil stamping lends an air of prestige and opulence by incorporating metallic accents that shimmer and gleam.

To add a three-dimensional depth and tactile interest, the options of embossing and debossing come into play. Embossing creates raised areas that lend a tactile quality, inviting exploration by touch, while debossing impresses designs into the surface, adding an elegant subtlety that can enhance your branding or artwork.

Moreover, the strategic application of spot UV brings an element of contrast and emphasis to specific areas of your packaging, creating striking highlights and accents that command attention.

By incorporating these diverse methods of finishing onto your paper tube packaging, you not only ensure its durability and protection but also transform it into a captivating and unique visual statement that sets your brand apart from competitors. Whether it's the understated elegance of matte lamination, the captivating allure of glitter coating, or the tactile richness of embossing, each technique contributes to a multi-dimensional and captivating packaging experience that resonates with your audience, leaving a lasting impression that speaks volumes about your brand's commitment to quality and innovation.

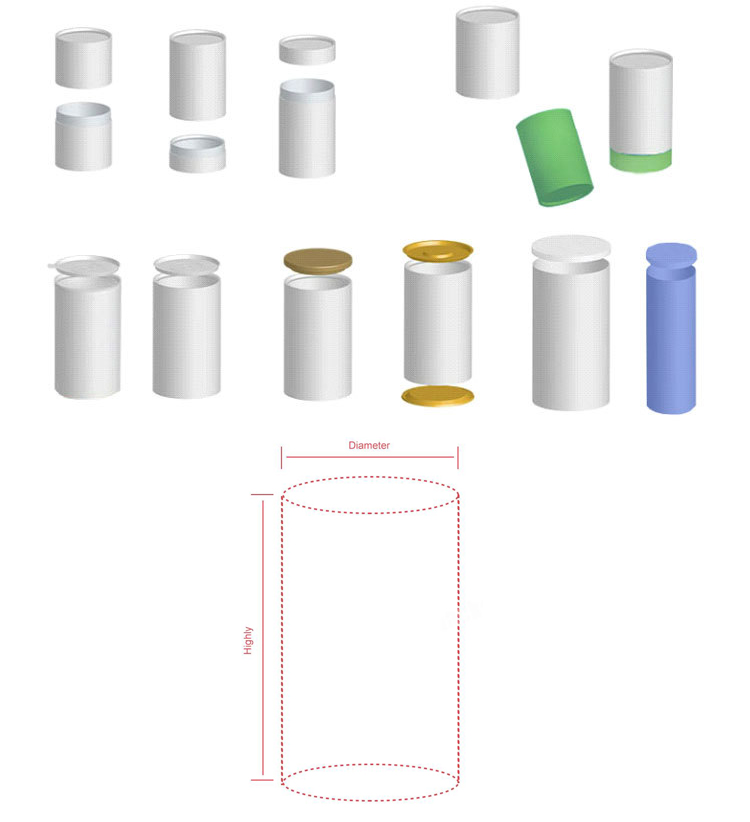

Lids Options of Paper Tube Packaging:

In the realm of paper tube packaging, versatility reigns supreme. To cater to the diverse needs and purposes that these cylindrical containers serve, our approach is multifaceted, ensuring that each paper tube box is not just a vessel but a tailored solution for specific applications.

For the conventional paper tube boxes, we employ a fitting paper cap. This cap, seamlessly integrated into the design, provides a simple yet effective closure, safeguarding the contents within while maintaining the structural integrity of the packaging. It's a practical choice, ideal for a wide array of uses and industries where functionality meets reliability.

When it comes to food-grade paper tube packaging, the requirement extends beyond mere functionality to the realm of safety and convenience. For these specialized containers, we utilize a peel-off lid that not only seals the contents securely but also offers a user-friendly experience. This innovative design ensures easy access to the consumables inside while preserving freshness and adhering to the highest standards of hygiene.

Tea enthusiasts often seek packaging that complements the essence and prestige of their beloved beverage. Hence, our tea paper tubes come adorned with metal tinplate lids. These lids don't just seal; they elevate the packaging, embodying a sense of tradition and sophistication that aligns perfectly with the ritual of brewing and enjoying fine teas.

The world of wine, with its rich heritage and cultural significance, demands packaging that reflects its prestige. Thus, our wine paper tube boxes feature lids crafted from wood and bamboo. These natural elements not only provide a secure enclosure but also add an organic, artisanal touch that complements the elegance of the bottled contents. The marriage of craftsmanship and functionality in these lids ensures that the packaging becomes an integral part of the overall wine experience.

By offering this spectrum of lid options for paper tube packaging, we pride ourselves on meeting and surpassing the diverse needs and preferences of our clientele. Whether it's the simplicity of a paper cap, the practicality of a peel-off lid, the sophistication of metal tinplate, or the organic allure of wood and bamboo, each lid is carefully selected and designed to harmonize with the specific use case, ensuring that our clients receive not just a container but a bespoke solution that embodies quality, functionality, and aesthetic appeal.

Customizable Options of Cardboard Tube:

When it comes to crafting paper tube packaging, our dedication to customization knows no bounds. We understand that the smallest details can make a world of difference, and that's why we offer an array of options for every component of your paper tube.

Let's start with the edges—those subtle yet impactful details that can transform the entire look and feel of your paper tube. The rolled edge and flat edge options available for both the paper tube cap and neck serve a dual purpose. Not only do they enhance the aesthetic appeal, but they also contribute to the user-friendliness of the packaging. These edges lend a sense of refinement while ensuring ease of handling, adding an extra touch of elegance to the overall design.

Moving inward, the inner wall of the paper tube holds significance beyond structural support. For standard applications, we offer common art paper—a reliable choice that provides a clean canvas for printing and branding. However, when it comes to specialized purposes such as food-grade packaging, our repertoire expands. Our food-grade paperboard options include an array of choices tailored to specific needs. For instance, when housing protein powder, food supplements, or spices, we offer aluminum foil lining, ensuring optimal protection and preservation of contents. In the case of salt packaging, wax paper becomes the preferred inner wall option, providing the necessary barrier and maintaining product integrity. Moreover, the versatility of our offerings extends to kraft paper and white cardboard stock, presenting a spectrum of possibilities to match your unique paper tube design requirements.

As for the bottom of the paper tube, we recognize the diverse needs of different products and purposes. Our customizable options cater to various functionalities. A paperboard bottom suffices for simpler products, providing adequate support while maintaining cost-effectiveness. For wine bottle packaging, we elevate the sophistication with a metal tinplate bottom, aligning with the premium nature of the contents. When it comes to packaging food products, particularly those demanding an added layer of protection, the aluminum bottom becomes the ideal choice, ensuring both safety and durability.

Crucially, every aspect of our paper tubes is fully customizable, allowing our clients to exercise their creative freedom and tailor each component according to their precise requirements. From edges to inner walls and bottoms, our commitment to flexibility and quality ensures that your paper tube packaging isn't just a container—it's a meticulously crafted reflection of your brand's vision and values.

Dimension Options of Cardboard Cylindrical Boxes:

When delving into the realm of paper tube packaging, the breadth of customization options truly unveils a world of possibilities. Our commitment to versatility is reflected not just in the aesthetic details but also in the very structure and dimensions of the paper tubes we offer.

Let's explore the structural options available to cater to diverse needs. Among the three common types of paper tube boxes, customization knows no bounds. The two-piece structured paper tubes exude simplicity yet efficiency. Their seamless construction offers both practicality and a sleek appearance, making them ideal for a wide range of products. Moving on to the three-piece structured paper tubes, these configurations add another layer of versatility. With separate lids and bases, they offer enhanced accessibility and customization possibilities, allowing for unique designs that perfectly encapsulate your brand's identity. Lastly, the telescope structured paper tubes, with their telescopic design, provide an added layer of sophistication. Their ability to extend or contract makes them particularly suitable for products that vary in height or those requiring an adjustable packaging solution.

Moreover, the customization doesn't end there. When it comes to dimensions, our flexibility ensures that each paper tube is tailored to your exact specifications. You have the freedom to customize not just the height and diameter but also the thickness of the paper tube walls. This level of customization empowers you to create packaging that perfectly accommodates your product, whether it's a snug fit for a delicate item or a robust housing for a substantial product. The ability to fine-tune these dimensions ensures that your paper tube isn't just a container but a tailored solution that offers the perfect balance of protection, presentation, and practicality.

This wide array of structural options and customizable dimensions allows us to collaborate closely with our clients, ensuring that every paper tube we create is a unique embodiment of their vision. Whether it's the simplicity of a two-piece design, the versatility of a three-piece structure, or the sophistication of a telescope structure, combined with the freedom to dictate the height, diameter, and thickness, we strive to provide a canvas for creativity and functionality that exceeds expectations. From concept to creation, our goal is to craft paper tube packaging that not only houses your product but also becomes an integral part of its presentation, enhancing its value and appeal on every level.

Information About Paper Tube Factory:

As a leading supplier of custom paper tube packaging, we specialize in catering to the diverse needs of the beauty, health, and food markets. Our manufacturing facilities are strategically situated in Shenzhen and Dongguan, China, spanning an expansive 10,000 square meters and powered by a dedicated workforce of 500 skilled individuals. What sets our factory apart is our proud certification of IS9001:2015, marking us as the pioneering dust-free workshop for paperboard tube packaging.

Our ethos revolves around the belief that meticulous attention to the production process can transform even a paperboard tube packaging into a powerful brand asset. By streamlining production, optimizing costs, and refining every detail of our manufacturing, we are committed to assisting brands in elevating their visibility and resonance through our packaging solutions.

At our core lies an unwavering commitment to providing our customers with competitive prices, uncompromising quality in product packaging, and exceptional service. We strongly advocate that, through our paperboard tube packaging, brands can not only deliver superior products but also contribute significantly to environmental conservation. Our conviction is rooted in the belief that paperboard packaging will undoubtedly supersede plastic in the future, making a substantial contribution to global sustainability efforts.

Frequently Asked Questions About Paper Tube:

Question A: What range of cardboard tube sizes do you offer?

Answer A: Our production spans from 22mm to 303mm in internal diameter for cardboard tubes. Detailed information regarding available paper tube sizes corresponding to each style of cardboard tube can be accessed on our sales team dedicated to each product.

Question B: Do your paper tubes align with environmental standards?

Answer B: Our cardboard tubes champion eco-friendliness by being entirely plastic-free and crafted from 100% cardboard. This composition ensures they are fully recyclable and biodegradable, contributing positively to sustainability efforts.

Question C: In what industries are your cardboard tubes employed?

Answer C: Our cardboard tubes serve diverse industries, including cosmetic packaging, spice containment, food supplements, protein powder storage, coffee preservation, perfume housing, cardboard tube beer packaging, and any sector seeking cardboard tubes with lids. Additionally, our push-up cardboard tubes are particularly suited for balms and deodorants, offering a practical solution.

Question D: Do you offer personalized printing on cardboard tubes?

Answer D: Absolutely! We specialize in creating custom-printed cardboard tubes tailored to your specific packaging requirements. Our aim is to assist you in leaving a lasting impression, ensuring that your products stand out on shelves and resonate with your customers through top-quality, innovative packaging solutions.

Question E: What types of paper tube styles can you produce?

Answer E: We offer a variety of styles, including 1-piece structured tubes featuring metal or plastic closures. Additionally, our range extends to 2-piece structured telescoping tubes, where the cap snugly fits atop the base when the tube is closed. These tubes come with options for straight or rolled edges on the top and bottom. Moreover, we craft 3-piece telescoping tubes, providing a flush-fit appearance as the cap securely fits on top of the "lip." These tubes also offer the choice between rolled or straight top and bottom edges for added customization.

Question F: Do your tubes comply with food-grade safety standards?

Answer F: Absolutely, we offer customizable tubes designed for food-grade safety. Our completely tailored tubes feature aluminum foil and PE lining, ensuring a food-safe and oil-resistant inner barrier. Typically, these tubes are sealed after filling to guarantee an airtight environment. Sealing methods include the use of metal discs, requiring specialized equipment, or shrink wrapping. Our minimum order quantity for these specialized food-grade tubes is 2500 pieces.

Alternatively, for an additional layer of food safety and prolonged shelf life, you have the option to package your product in a sealed bag before inserting it into the tubes. This dual-layer approach enhances food safety measures, ensuring the utmost protection for your products.

Question G: What is your minimum order quantity?

Answer G: At our factory, we prioritize flexibility to meet our customers' needs. We don't impose a minimum order quantity. Whether you require a single tube or 10,000 tubes, we are dedicated to accommodating your specific requirements and providing the assistance you need.

Question H: What is the turnaround time for my order?

Answer H: Typically, you can expect to receive your finished samples of paper tubes within 3-4 days as a standard timeframe. Once you've approved the samples, the completion of the mass production typically takes around 12 days. This ensures that your finalized order is processed efficiently and meets your specifications before the mass production phase begins.

Question I: Can I preview my design on the paper tube before production?

Answer I: Absolutely! To ensure your complete satisfaction with the design, we provide a printed sheet via next day delivery. This allows you to visualize your printed design in its full glory before proceeding to production, ensuring that it aligns perfectly with your vision and expectations.

English

English Español

Español Português

Português Pусский

Pусский Français

Français Deutsch

Deutsch 日本語

日本語 한국어

한국어 Italiano

Italiano عربى

عربى